At the heart of every internal combustion engine lies the combustion chamber, where the magic of converting fuel into energy takes place. Among the diverse array of combustion chamber designs, the hemispherical configuration has long been revered for its exceptional efficiency and performance capabilities. In this introductory section, we embark on a journey to unravel the mysteries surrounding hemispherical combustion chambers, tracing their origins and understanding their significance in modern automotive engineering.

The term "hemispherical combustion chamber" refers to a design wherein the upper portion of the chamber resembles a half-sphere. This unique geometry promotes optimal airflow and fuel distribution, leading to improved combustion efficiency. The roots of the hemispherical design can be traced back to the early 20th century, with pioneers like Harry Ricardo experimenting with various chamber shapes to enhance engine performance.

The combustion chamber plays a pivotal role in determining the overall efficiency and power output of an engine. Its design directly influences factors such as flame propagation, air-fuel mixing, compression ratios, and heat dissipation, all of which are critical for maximizing performance while minimizing emissions and fuel consumption.

Understanding Hemispherical Combustion Chambers

Explanation of Hemispherical Design

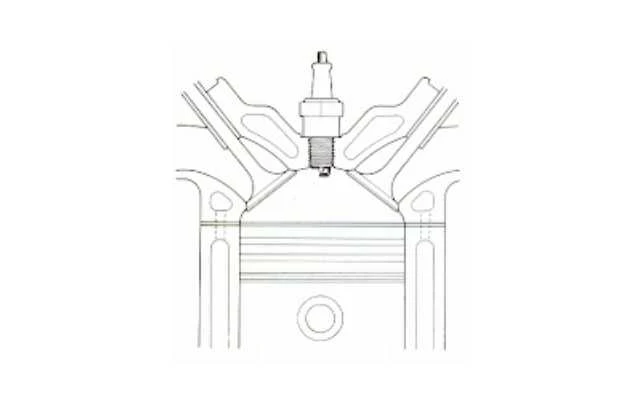

The hallmark feature of a hemispherical combustion chamber is its dome-shaped configuration, resembling half of a sphere. This design promotes superior turbulence within the chamber, ensuring thorough mixing of air and fuel for efficient combustion.

Historical Context and Evolution

The concept of the hemispherical combustion chamber traces its origins to early experiments in engine design. Over the years, advancements in engineering and technology have refined the hemispherical design, allowing for greater precision and optimization in modern engines.

The hallmark feature of a hemispherical combustion chamber is its dome-shaped configuration, resembling half of a sphere. This design promotes superior turbulence within the chamber, ensuring thorough mixing of air and fuel for efficient combustion.

Historical Context and Evolution

The concept of the hemispherical combustion chamber traces its origins to early experiments in engine design. Over the years, advancements in engineering and technology have refined the hemispherical design, allowing for greater precision and optimization in modern engines.

Advantages of Hemispherical Combustion Chambers

Hemispherical combustion chambers offer a plethora of benefits, making them a preferred choice in high-performance engines.

Improved Flame Propagation

The hemispherical shape promotes rapid and uniform flame propagation across the combustion chamber, leading to more complete combustion and increased power output.

Enhanced Air-Fuel Mixing

The unique geometry of hemispherical chambers facilitates efficient mixing of air and fuel, ensuring homogeneous combustion and reduced emissions.

Higher Compression Ratios

Hemispherical chambers allow for higher compression ratios, thanks to their compact design and optimized combustion process. This results in improved engine efficiency and performance.

Efficient Heat Dissipation

The ample surface area provided by the hemispherical design facilitates effective heat dissipation, preventing hot spots and minimizing the risk of detonation.

The hemispherical shape promotes rapid and uniform flame propagation across the combustion chamber, leading to more complete combustion and increased power output.

Enhanced Air-Fuel Mixing

The unique geometry of hemispherical chambers facilitates efficient mixing of air and fuel, ensuring homogeneous combustion and reduced emissions.

Higher Compression Ratios

Hemispherical chambers allow for higher compression ratios, thanks to their compact design and optimized combustion process. This results in improved engine efficiency and performance.

Efficient Heat Dissipation

The ample surface area provided by the hemispherical design facilitates effective heat dissipation, preventing hot spots and minimizing the risk of detonation.

Comparison with Other Combustion Chamber Designs

While hemispherical combustion chambers offer numerous advantages, it's essential to compare them with other popular designs to understand their relative strengths and weaknesses.

Pent Roof

The pent roof design, characterized by its flat roof and steeply angled walls, offers good airflow and efficient combustion. However, it may not match the turbulence-generating capabilities of the hemispherical chamber.

Wedge

Wedge-shaped chambers feature a flat roof and wedge-shaped walls, promoting swirl and turbulence for enhanced combustion. While effective, they may not achieve the same level of efficiency as hemispherical designs.

Bathtub

Bathtub chambers, with their shallow, wide shape, prioritize low-end torque and fuel economy. While suitable for certain applications, they may sacrifice top-end power compared to hemispherical designs.

The pent roof design, characterized by its flat roof and steeply angled walls, offers good airflow and efficient combustion. However, it may not match the turbulence-generating capabilities of the hemispherical chamber.

Wedge

Wedge-shaped chambers feature a flat roof and wedge-shaped walls, promoting swirl and turbulence for enhanced combustion. While effective, they may not achieve the same level of efficiency as hemispherical designs.

Bathtub

Bathtub chambers, with their shallow, wide shape, prioritize low-end torque and fuel economy. While suitable for certain applications, they may sacrifice top-end power compared to hemispherical designs.

Key Components of Hemispherical Combustion Chambers

A deeper understanding of the key components within hemispherical combustion chambers is essential for optimizing engine performance.

Valve Layout and Angle

The positioning and angle of intake and exhaust valves play a crucial role in determining airflow dynamics and combustion efficiency within hemispherical chambers.

Piston Configuration

The shape and design of pistons must complement the hemispherical chamber geometry to maximize compression ratios and combustion efficiency.

Spark Plug Placement

Optimal positioning of spark plugs ensures efficient ignition and flame front propagation, contributing to smooth and consistent combustion.

The positioning and angle of intake and exhaust valves play a crucial role in determining airflow dynamics and combustion efficiency within hemispherical chambers.

Piston Configuration

The shape and design of pistons must complement the hemispherical chamber geometry to maximize compression ratios and combustion efficiency.

Spark Plug Placement

Optimal positioning of spark plugs ensures efficient ignition and flame front propagation, contributing to smooth and consistent combustion.

The Role of Pistons in Hemispherical Design

Pistons serve as integral components in hemispherical combustion chambers, interacting closely with the chamber geometry to optimize combustion processes.

Piston Bowl Shape and Interaction

The shape of the piston bowl must complement the hemispherical chamber to promote efficient airflow and combustion.

Clearance Considerations

Clearance between the piston and cylinder head is crucial to prevent interference and optimize compression ratios in hemispherical designs.

Impact on Compression Ratio

Piston design directly affects compression ratios in hemispherical chambers, influencing engine performance and efficiency.

The shape of the piston bowl must complement the hemispherical chamber to promote efficient airflow and combustion.

Clearance Considerations

Clearance between the piston and cylinder head is crucial to prevent interference and optimize compression ratios in hemispherical designs.

Impact on Compression Ratio

Piston design directly affects compression ratios in hemispherical chambers, influencing engine performance and efficiency.

Valve Configuration and Its Impact

The configuration of valves within hemispherical chambers is critical for achieving optimal airflow and combustion dynamics.

Valve Size and Shape

The size and shape of valves dictate airflow characteristics and combustion efficiency within hemispherical chambers.

Valve Timing

Precise timing of valve events is essential to synchronize airflow with piston movement and maximize combustion efficiency.

Flow Characteristics

Valve design influences airflow patterns within the combustion chamber, affecting turbulence and combustion stability.

The size and shape of valves dictate airflow characteristics and combustion efficiency within hemispherical chambers.

Valve Timing

Precise timing of valve events is essential to synchronize airflow with piston movement and maximize combustion efficiency.

Flow Characteristics

Valve design influences airflow patterns within the combustion chamber, affecting turbulence and combustion stability.

Spark Plug Placement for Optimal Ignition

Proper positioning of spark plugs is paramount for ensuring reliable ignition and efficient combustion within hemispherical chambers.

Importance of Proper Spark Plug Positioning

The strategic placement of spark plugs facilitates rapid and uniform flame propagation, contributing to efficient combustion.

Ignition Timing and Flame Front Propagation

Timely ignition and propagation of the flame front are critical for maximizing power output and engine efficiency.

The strategic placement of spark plugs facilitates rapid and uniform flame propagation, contributing to efficient combustion.

Ignition Timing and Flame Front Propagation

Timely ignition and propagation of the flame front are critical for maximizing power output and engine efficiency.

Fuel Injection Strategies for Hemispherical Chambers

The choice between direct injection and port injection can significantly impact combustion performance in hemispherical chambers.

Direct Injection vs. Port Injection

Direct injection offers precise control over fuel delivery and combustion dynamics, making it ideal for optimizing performance in hemispherical chambers.

Spray Pattern Optimization

Optimizing fuel spray patterns enhances air-fuel mixing and combustion efficiency within hemispherical chambers.

Combustion Control Systems

Advanced combustion control systems leverage sensor feedback and real-time adjustments to optimize fuel delivery and combustion processes in hemispherical chambers.

Direct injection offers precise control over fuel delivery and combustion dynamics, making it ideal for optimizing performance in hemispherical chambers.

Spray Pattern Optimization

Optimizing fuel spray patterns enhances air-fuel mixing and combustion efficiency within hemispherical chambers.

Combustion Control Systems

Advanced combustion control systems leverage sensor feedback and real-time adjustments to optimize fuel delivery and combustion processes in hemispherical chambers.

Performance Tuning with Hemispherical Combustion Chambers

Unlocking the full potential of hemispherical combustion chambers requires careful tuning and optimization across various engine subsystems.

ECU Tuning

Fine-tuning engine control parameters through electronic control unit (ECU) calibration optimizes performance and efficiency in hemispherical chambers.

Cylinder Head Modifications

Modifying cylinder head components such as valves, ports, and combustion chambers can unleash additional power and efficiency in hemispherical engines.

Exhaust System Upgrades

Optimizing exhaust flow and backpressure through aftermarket exhaust system upgrades complements the performance gains achieved with hemispherical combustion chambers.

Fine-tuning engine control parameters through electronic control unit (ECU) calibration optimizes performance and efficiency in hemispherical chambers.

Cylinder Head Modifications

Modifying cylinder head components such as valves, ports, and combustion chambers can unleash additional power and efficiency in hemispherical engines.

Exhaust System Upgrades

Optimizing exhaust flow and backpressure through aftermarket exhaust system upgrades complements the performance gains achieved with hemispherical combustion chambers.

Challenges and Considerations

While hemispherical combustion chambers offer numerous advantages, they also present unique challenges and considerations for engineers and tuners.

Combustion Efficiency at Various Loads

Ensuring consistent combustion efficiency across a wide range of engine loads and operating conditions is essential for maximizing performance and minimizing emissions in hemispherical combustion chambers.

Cooling Requirements

The efficient dissipation of heat generated during combustion is crucial for preventing engine overheating and ensuring long-term durability. Proper cooling system design and management are imperative for maintaining optimal temperatures within hemispherical chambers.

Emissions Control

Meeting stringent emissions regulations necessitates effective control of pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Advanced exhaust aftertreatment systems and precise engine calibration are indispensable for achieving compliance without compromising performance.

Ensuring consistent combustion efficiency across a wide range of engine loads and operating conditions is essential for maximizing performance and minimizing emissions in hemispherical combustion chambers.

Cooling Requirements

The efficient dissipation of heat generated during combustion is crucial for preventing engine overheating and ensuring long-term durability. Proper cooling system design and management are imperative for maintaining optimal temperatures within hemispherical chambers.

Emissions Control

Meeting stringent emissions regulations necessitates effective control of pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). Advanced exhaust aftertreatment systems and precise engine calibration are indispensable for achieving compliance without compromising performance.

Future Prospects and Innovations

As automotive technology continues to evolve, hemispherical combustion chambers are poised to play a significant role in shaping the future of internal combustion engines.

Integration with Hybrid and Electric Technologies

The versatility and efficiency of hemispherical combustion chambers make them well-suited for integration with hybrid powertrains and range-extender engines. By optimizing combustion efficiency, these engines can complement electric propulsion systems, enhancing overall vehicle efficiency and performance.

Advancements in Material Science

Ongoing advancements in material science offer the potential to further improve the performance and durability of hemispherical combustion chambers. Lightweight yet robust materials can enable higher operating temperatures and tighter tolerances, leading to enhanced efficiency and reliability.

Computational Fluid Dynamics (CFD) Simulations

The advent of computational fluid dynamics (CFD) simulations empowers engineers to precisely model and optimize combustion processes within hemispherical chambers. By leveraging simulation-driven design, manufacturers can accelerate development cycles and fine-tune chamber geometry for optimal performance and efficiency.

The versatility and efficiency of hemispherical combustion chambers make them well-suited for integration with hybrid powertrains and range-extender engines. By optimizing combustion efficiency, these engines can complement electric propulsion systems, enhancing overall vehicle efficiency and performance.

Advancements in Material Science

Ongoing advancements in material science offer the potential to further improve the performance and durability of hemispherical combustion chambers. Lightweight yet robust materials can enable higher operating temperatures and tighter tolerances, leading to enhanced efficiency and reliability.

Computational Fluid Dynamics (CFD) Simulations

The advent of computational fluid dynamics (CFD) simulations empowers engineers to precisely model and optimize combustion processes within hemispherical chambers. By leveraging simulation-driven design, manufacturers can accelerate development cycles and fine-tune chamber geometry for optimal performance and efficiency.

Conclusion

In conclusion, hemispherical combustion chambers stand as a testament to the relentless pursuit of efficiency and performance in automotive engineering. With their unique geometry and inherent advantages, they offer a compelling solution for maximizing power output while minimizing emissions and fuel consumption. By understanding the intricacies of hemispherical design, optimizing key components, and embracing emerging technologies, engineers can unlock new levels of efficiency and performance in internal combustion engines. As we look towards the future, the evolution of hemispherical combustion chambers promises to shape the automotive landscape for years to come, driving innovation and pushing the boundaries of what's possible on the road and beyond.